VALUATION EQUIPMENT OF MECHANICAL PROPERTIES AND RESIDUAL STRESS USING IIT AT MICRO-SCALE

Mechanical Properties Test Micro-AIS evaluate tensile properties and residual stresses of the test subjects of very small dimensions (Micrometers), such as fine-welded parts and coated layers.

Through the Vision system automatic stages, the test position can be identified and designated. Moreover, precision test for major parts is made available through automatic and screening tests.

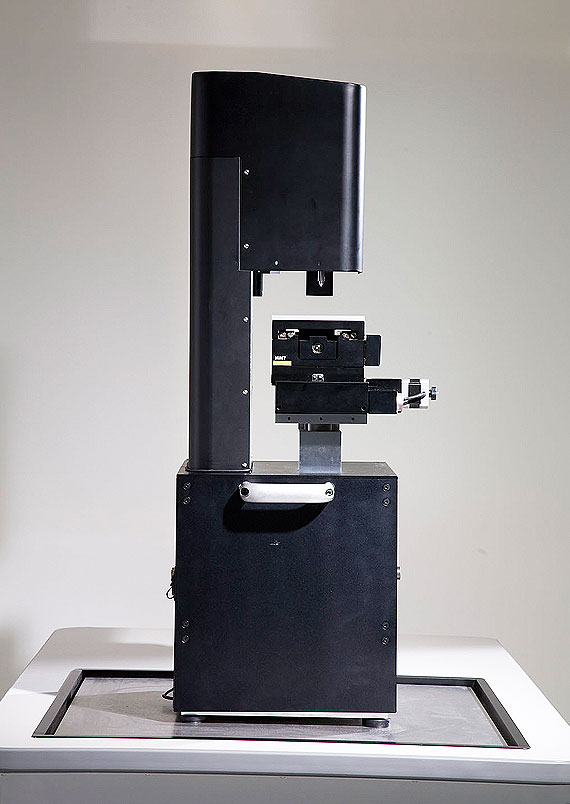

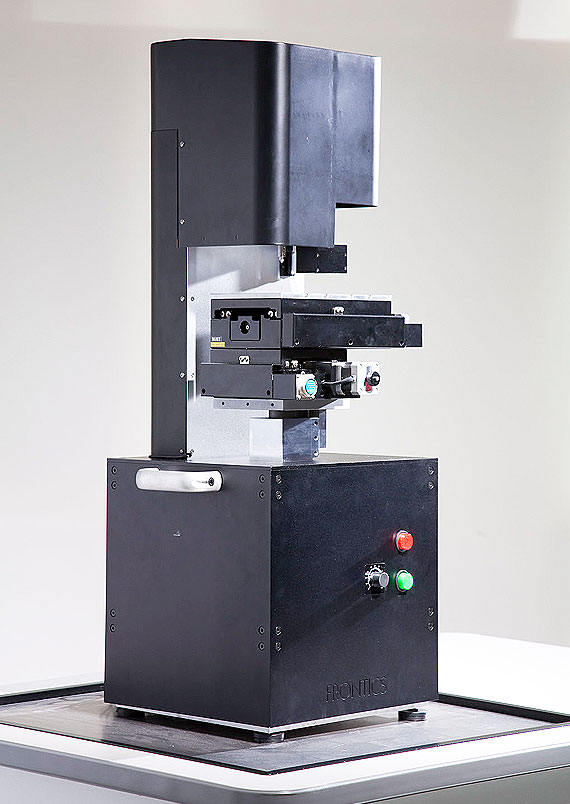

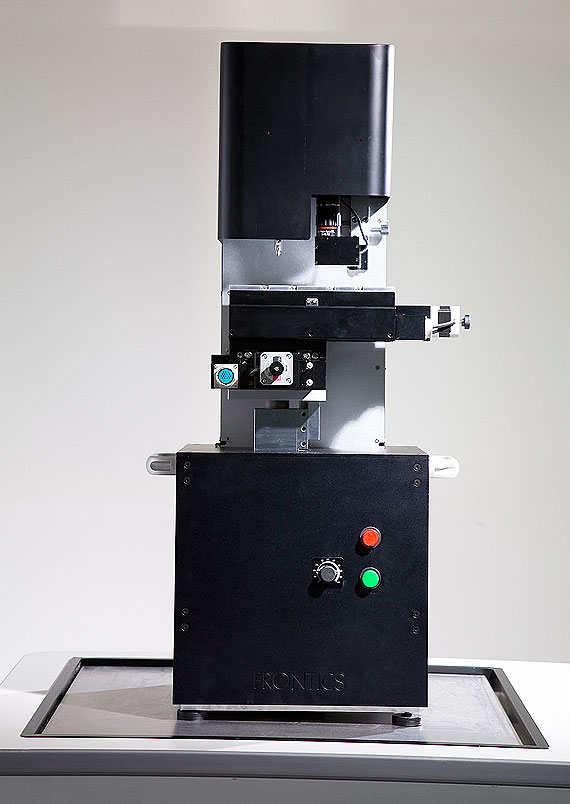

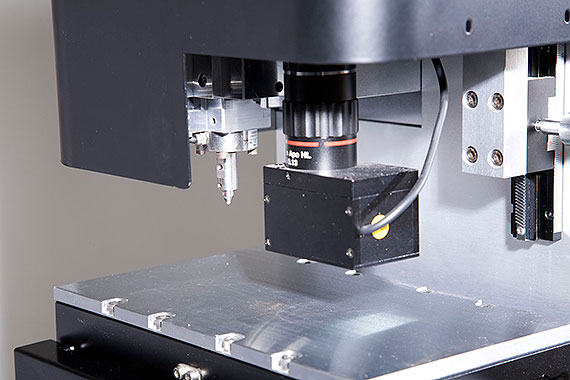

Micro AIS

Hardware

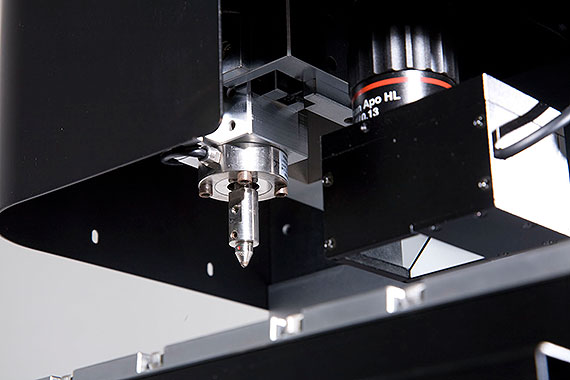

- Non-destructive Residual Stress evaluation for Micro scale material

- Laboratory type IIT system (Automatic test module)

- Non-contact displacement sensor and work space efficiency

- High resolution vision(Max zoom: X1200)

- Manual operation for Vertical Z-Axis stage moving

- High quality anti-dust system

- Uninterruptable power supply(option)

- Adoptable to Temperature chamber tester(option: -150℃ ~ 1000℃)

Model

Micro AIS

Size (Weight)

13 x 12 x 35 inch (280 lbs)

Maximum load

4.3 lbf

Resolutions (Load/Depth)

0.03 gf / 0.01 um

Full stroke

1 inch

Loading rate

0.1 ~ 20 mm/min

Communication

RS-422 (USB)

Data Acquisition rate

100 points/sec

Power

AC 110 ~ 220V

Analyzing computer

Desktop

Indenter

Micro Vickers Indenter

Software

- Residual stress software based on the theory of IIT (Instrumented Indentation Technique)

- Possible to measure and analyze in real time by using a desktop

- Possible to load All-in-one software (Tensile properties, fracture toughness software)

- One-click automatic test (Full automatic software) and adopting software to change a testing location automatically.

- Embed auto multi-mapping, selecting, image test modules

- Possible to perform all of things such as testing, analyzing, collecting DB and making a report with one software.

- Embedded functions such as auto-malfunctioning and error data check.

- Possible to apply a high & low temperature chamber system and embed checking software. (When embedding a high & low temperature chamber system)